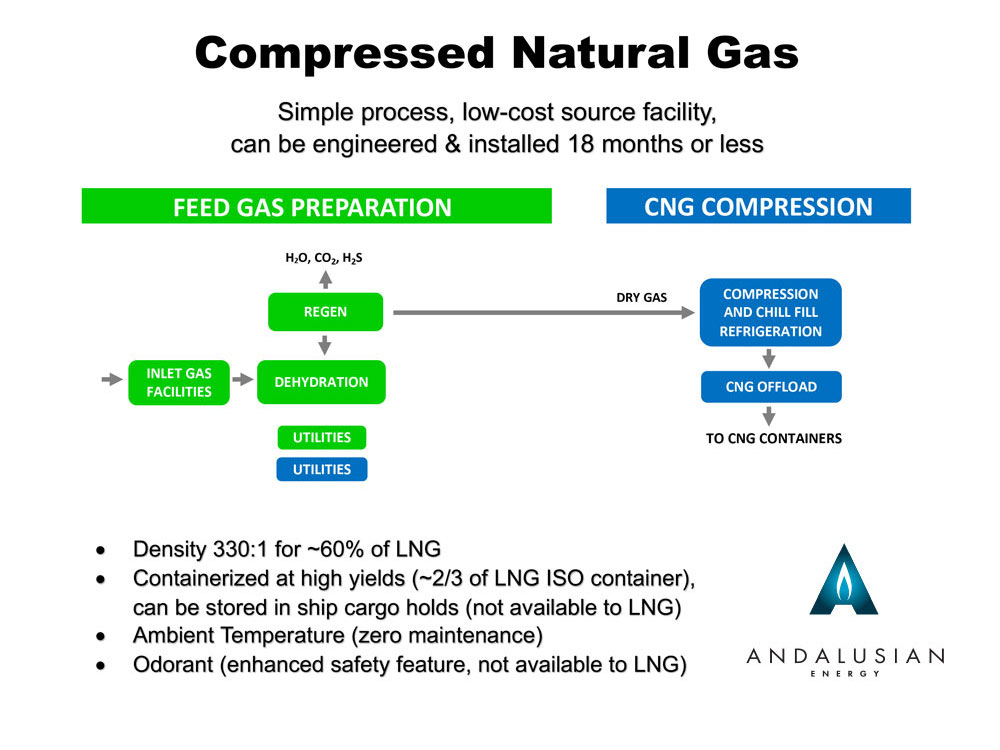

CNG Process

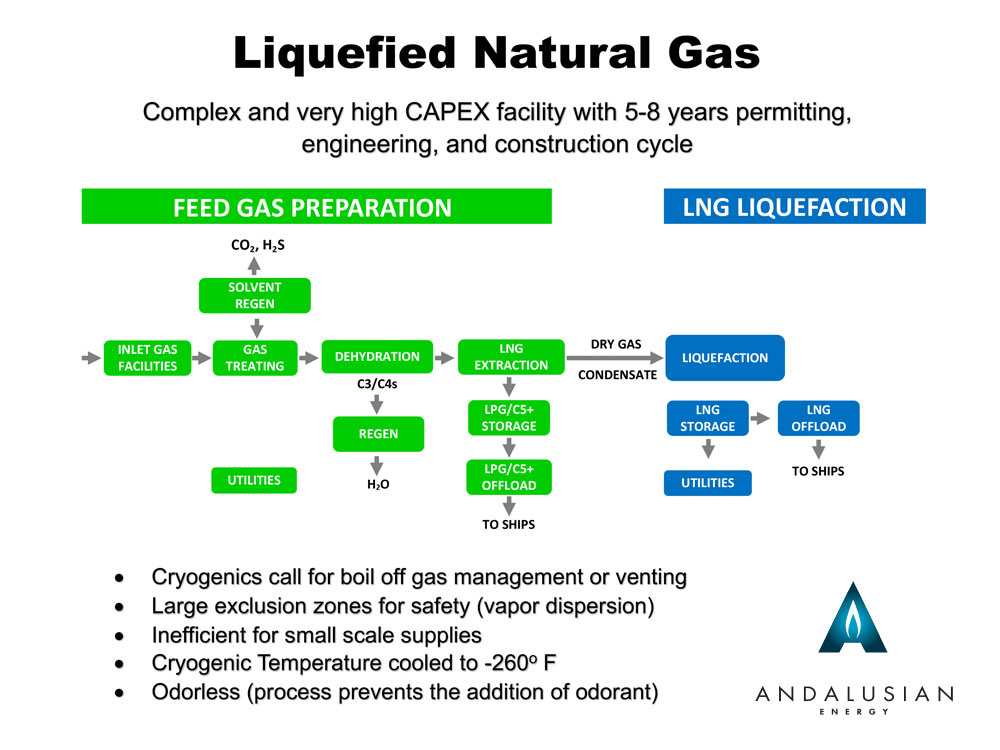

The above illustration describes the comparison of the CNG compression process and the LNG liquefaction process and demonstrates the infrastructure, production, and transportation advantages of CNG. Simply put, compression is less expensive than liquification, requires less energy, and eliminates the need for costly regasification infrastructure.

In the LNG liquefaction process, the feed gas requires thorough processing including inlet scrubbers, amine treatment for acid gas removal, dehydration for water removal, carbons beds for mercury removal, LPG extraction, LPG/C5+ storage, LPG offload, chilling, liquefaction, nitrogen rejection, LNG storage, LNG offload, etc. An LNG liquefaction plant project is highly complex and capital-intensive. A typical LNG project may take five to eight years of permitting, engineering, and construction, including the labor-laden and time-consuming undertaking of the FERC regulatory process.

In comparison, a CNG compression facility is relatively simple. The CNG compression station can be constructed within an 18-month period, excluding permitting. Since CNG is compressed and stored at ambient temperature, it avoids boil-off gas generation and has a minimum safety zone due to negligible vapor dispersion events and thermal radiation. Also, mercaptan-based odorant may be added to CNG to improve the ease of detection.

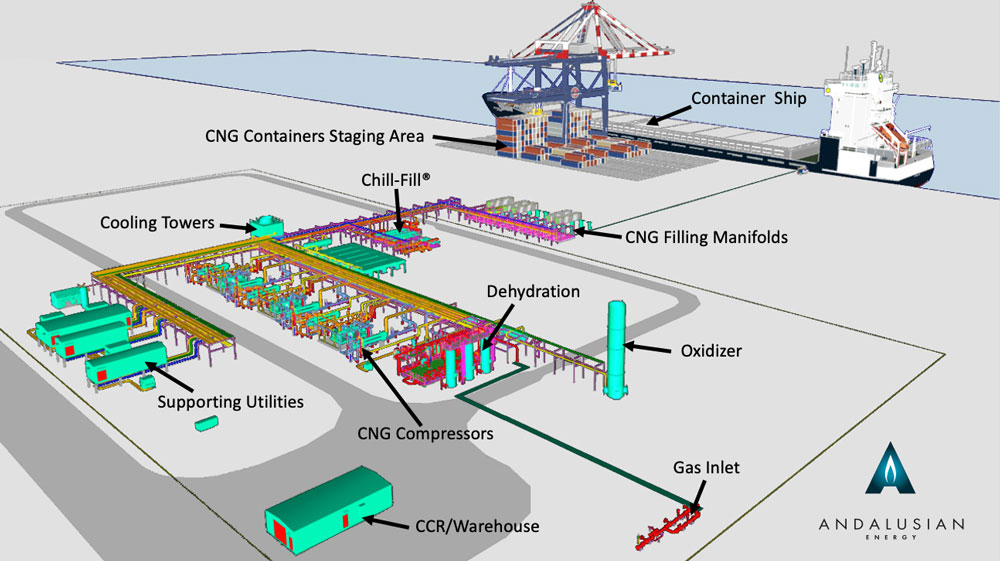

Andalusian Energy’s Proposed Port of Mobile CNG Compression Facility

Andalusian Energy Port of Mobile CNG Compression Facility

The above illustration shows a 3D model of Andalusian Energy’s proposed CNG compression facility within the footprint of the Port of Mobile’s ICTF. As seen in the 3D model, the straightforward production process requires only five steps:

- Feed gas is introduced into the plant from the metering station.

- Absorption dehydration further treats the pipeline-quality gas.

- The dehydrated gas flows into the CNG main compressors in parallel, driven by either electric motors or gas engines (used for blackstart and redundancy in case of electrical failures), producing the high-pressure CNG product.

- The CNG is cooled to counter the compression heat generated during loading into CNG containers.

- Fully loaded CNG containers are stored at the staging yard before loading by cranes onto an ocean-going container ship.

Fiberglass composite cylinders are currently the only viable alternative in a maritime ship-based solution (virtual pipeline) to transport CNG. And they are affordable.

Andalusian’s Chill-Fill® process technology for CNG was initially disclosed in 2015 at an ASME (American Society of Mechanical Engineers) conference, https://doi.org/10.1115/POWER2015-493868. Additionally, Chevon investigated and provided technical approval for the system to enable sales of natural gas to potential end-users in Central America and the Caribbean. Andalusian management team members have deployed the system in two prior US compression facility installations.

This agile and modular system can quickly expand within months – rather than years – compared to greenfield LNG.